I did a thing – I’ve entered a Spoonflower design contest!

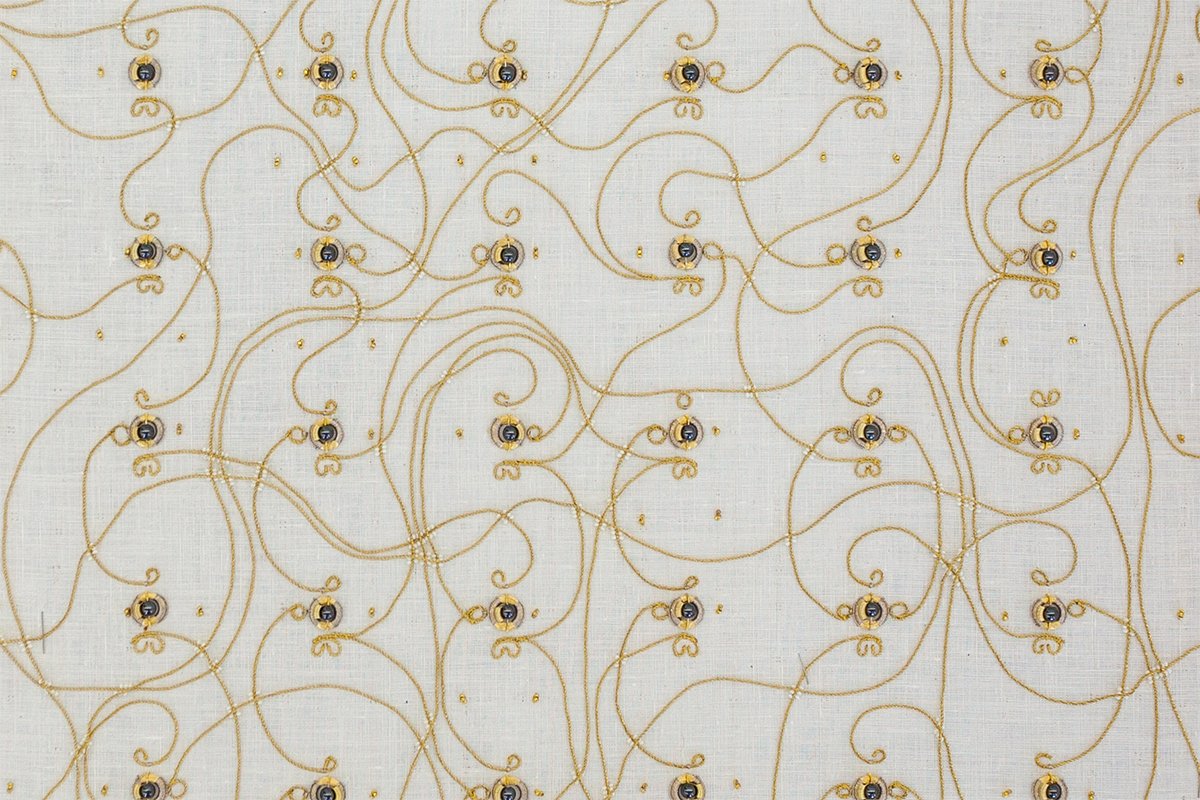

It’s the Spoonflower Crustation Cottage Core design challenge, running May 9 – 21, 2024. My design is called New Orleans Seafood Damask.

Even if I don’t get a single vote, I’m pretty pleased with myself. But you know, if you like my design, thank you – you should vote for it! (Go ahead, the link is right here. I’ll wait.). There are some fun designs available.

(bottom left) Full pattern repeat example; (bottom right) This color combo didn’t make the cut. I like it, but it was too flat and lacks pop.

I love fabric design, but the truth is, I don’t draw terribly well. I never learned and I’m not very disciplined. Every time I try, my practicing lasts for maybe a week, then I get distracted by the next shiny thing or idea and off I go. This time I actually managed to complete something. (Pats self on back).

This design has been kicking around in my head since about… 2017… ever since I got a neat old chair that I decided to reupholster. Ask me if I’ve ever done a full reupholster from the frame out? Nope; just recovering jobs. Have I finished it? No. But I took very detailed pics of the teardown and have analysis of the age of the materials and design that I’ll share later. I also have 90% of the materials I need to do the job. All I need is some twine for retying the springs and the outer fabric. Aaaannd that’s where I got stuck – the design.

I knew I wanted something bold and New Orleans themed. I wanted Mardi Gras colors. Sadly, every version I tried was too busy. I was trying to shoe-horn four delicious sea creatures (the four food seasons of NOLA) into the design and have a seamless repeating damask pattern. I went through about 4 versions and three color schemes before I saw the prompt for the contest. By that point, I knew I had to simplify. It took me a while to settle on the colors (not at all what I’d expected) and tweak both the size so it repeats exactly the way I wanted, and the details so the two figures stand out and still coordinate. Calling it seafood based cottage core might be a bit of a stretch, but oh well.

Now the question is, how will it look on that chair? Or should I do an accent wall in my bathroom with it? NOLA here I come!

One last thing…

In case you’re interested, here are the details of the design, from my Spoonflower shop:

The scale is shown as a 7″ x 7″ repeat, with the figures at about 6″ high, but can be sized up to a 9″ x 9″ repeat, with each figure measuring about 8 1/2″ inches high.

The colors used are a deep ocean blue, with a red crawfish (it’s okay if you see him as a lobster), and a teal Fleur de lis. Overall the design has seven colors: one blue, one teal, two turquoise, one red, a pinky-red and white. Hex codes available upon request.

Suitable for home decor or whatever your heart desires. I think it would make a fun accent wallpaper in a bathroom or laundry room and I’m seriously considering scaling it down for a chair I want to reupholster with wild New Orleans flair!

Contact me for scaling and color options.